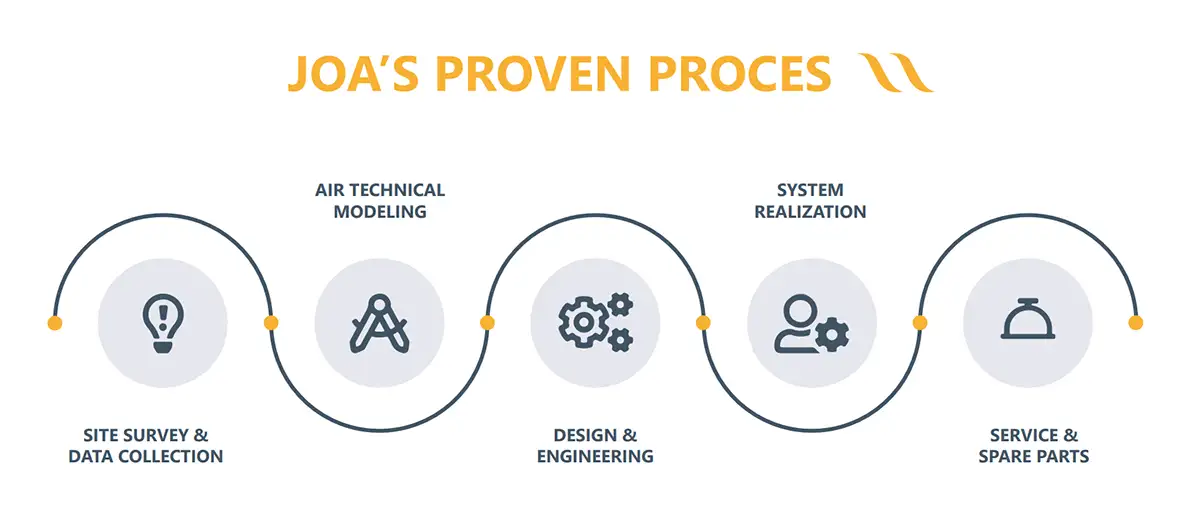

Introduction to Pre-Engineering Studies

A Pre-Engineering Study lays the groundwork for substantial upgrades or new systems in emission control, energy efficiency, and workplace safety at your industrial site. By engaging in a comprehensive evaluation before implementing changes, JOA Air Solutions ensures that every modification is perfectly tailored to your specific needs, thereby maximizing operational efficiency and compliance.

What is a Pre-Engineering Study?

A pre-engineering study evaluates an industrial site before major upgrades, focusing on emission control, energy efficiency, and safety. This step identifies optimal improvements and technologies, ensuring efficient operations and environmental compliance.

Read more about how a Pre-Engineering Study leads towards better systems:

Why Opt for a Pre-Engineering Study?

Data-driven Decisions

Base your facility upgrades on accurate measurements and detailed Air Technical Modeling, eliminating guesswork for assured successful outcomes.

Guaranteed Outcomes

Receive process guarantees that offer certainty in performance improvements and regulatory compliance.

Informed Investments

Make financially sound decisions with a clear understanding of the costs and benefits associated with your facility’s upgrades.

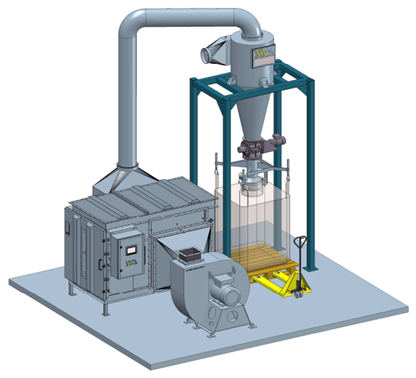

Adjusted to your requirements

Don’t settle for standard equipment that either extracts too much or too little to be efficient. At JOA, we believe that every larger or complex industrial process deserves a tailored extraction system.

Core Components of a Pre-Engineering Study

What can you expect from a Pre-Engineering Study from JOA Air Solutions?

- Site Survey & Data Collection

- Collect vital data on existing site conditions focusing on particle characteristics, extraction points, volumes and flow velocities.

- Conduct guided evaluations and laboratory tests to establish a comprehensive dataset for modeling.

- Inspection on existing equipment

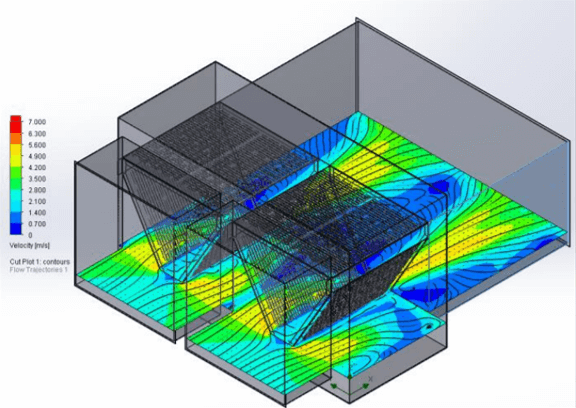

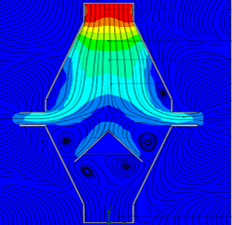

- Air Technical Modeling & Analysis

- Identification of bottlenecks in your current process

- Utilize advanced, proprietary software to simulate air flows and model potential improvements.

- This critical step visualizes the impact of proposed changes, ensuring effective and efficient outcomes.

- Analyze current operations and develop an improvement plan detailing multiple upgrade scenarios.

- Each scenario evaluates cost-effectiveness, potential returns, and compliance with safety and environmental standards.

- Reporting and Decision Support

- Conclude the study with a detailed report that includes findings, actionable recommendations, and a budget quotation.

- This report supports your decision-making process, providing a clear path forward and concept design without reliance on intuition.

Benefits of Conducting a Pre-Engineering Study with JOA

- Risk Reduction: Lower the risk of project failure by fully understanding potential outcomes before committing resources.

- Cost Efficiency: Pinpoint the most cost-effective solutions and comprehend their financial implications prior to execution.

- Compliance & Safety: Ensure that all proposed changes not only meet regulatory standards but also advance safety protocols for operational staff.

FAQ

Q. What do I get from a Pre-Engineering Studies

A. A Pre-Engineering Study is always tailored to your specific requirements. JOA Engineers will visit your site, take measurements and gather input for Air Technical Modeling. Based on the data, calculations are made on flow rate, energy recovery, velocities, ROI and more. During a 50% meeting, we update you on our findings and align expectations before finalizing a concept design and budget quotation. Read more about what to expect here: https://joaairsolutions.com/blog/pre-engineering-study-better-extraction-systems/

Q. How much time will a Pre-Engineering Study cost me

A. Generally, a Pre-Engineering Study can be conducted within 2-3 months. We ask you for input regarding P&ID, photo’s or videos, layout drawings, access to the site and sometimes interviews with the operators. Depending on the scale of the project, we need 1 or 2 days on-site. Our goal is to limit the time you need before completing the study.

Q. How extensive will the study be?

A. Sometimes, new clients are hesitant to conducting a Pre-Engineering study. Experiences from the past where an external ‘consultant’ came and wrote down findings you already know about are not helpful. Our goal is to exceed expectations as it gives us the opportunity to show our skills and expertise to also provide the best possible solution to your emission control or energy recovery challenges.

Q. Can I also just order a system without study?

A. Only in very rare cases we are able to come up with a suitable solution without first gain a thorough understanding of your site and processes. There are many suppliers of standardized equipment. JOA differentiates itself by diving deeper and create tailor-made solutions, optimizing your sites performance.